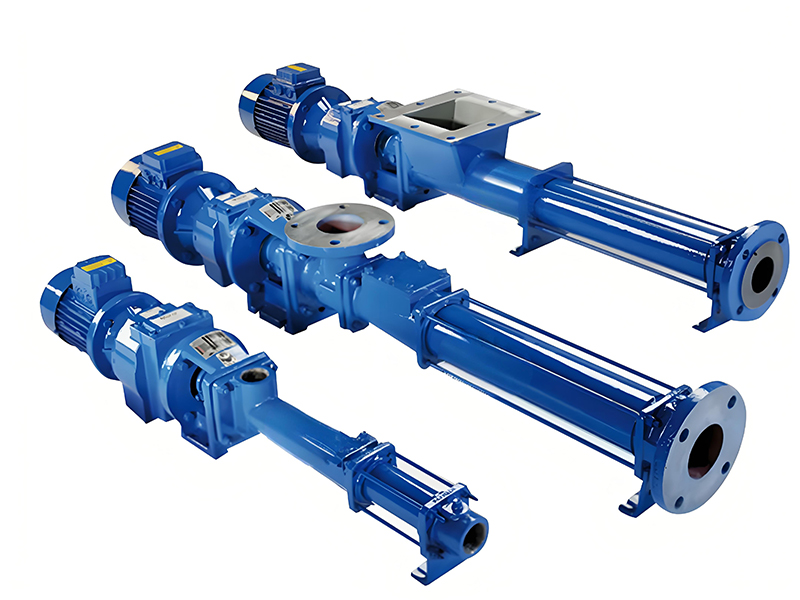

The Vertical Screw Pump with Pedestal is a robust, space-saving, and highly efficient positive displacement pump designed for continuous transfer of viscous, abrasive, and multiphase fluids. Its vertical installation with an integrated pedestal base provides excellent stability, compact footprint, and ease of maintenance, making it an ideal solution for industrial, wastewater, chemical, and food applications where space and reliability are critical.

Unlike traditional horizontal pumps, the vertical screw pump is configured with the motor mounted above the drive shaft, while the pump body is immersed in the medium. This arrangement allows for self-draining operation, reduced floor space, and easy integration into tanks, pits, or reactors. The pedestal design adds structural strength and supports the vertical alignment, ensuring smooth operation with minimal vibration.

The pump operates on the principle of progressive cavity motion, utilizing a helical rotor and stator assembly that forms continuous sealed cavities. As the rotor turns, these cavities move axially, gently conveying the fluid without pulsation or turbulence. This makes the Vertical Screw Pump with Pedestal suitable for shear-sensitive, viscous, or solid-laden fluids that cannot be handled effectively by centrifugal pumps.

With materials available in 304, 316L stainless steel, carbon steel, or abrasion-resistant alloys, the pump can be adapted for a wide range of industries. The design ensures low noise, high efficiency, and long service life, meeting the demanding requirements of modern processing facilities.

| Parameter | Specification |

Pump Type | Single-screw, vertical installation, pedestal-mounted |

Material | Stainless Steel 304 / 316L / Duplex / Carbon Steel |

Flow Range | 0.1 – 150 m3/h |

Pressure Range | Up to 2 MPa (20 bar) |

Temperature Range | -20°C to +120°C (optional high-temperature design up to 150°C) |

Viscosity Range | 1 cP – 100,000 cP |

Solid Content | ≤ 60% by volume |

Rotor Material | Stainless Steel / Chrome-Plated Alloy / Duplex |

Stator Material | Nitrile (NBR), EPDM, FKM, PTFE, or customized elastomer |

Seal Type | Mechanical seal / Packing seal / Cartridge seal |

Drive Type | Electric motor, geared motor, or VFD control |

Mounting Type | Vertical, with pedestal base support |

Surface Finish (Sanitary Model) | Ra ≤ 0.8 μm |

Cleaning System | CIP / SIP compatible (optional) |

The Vertical Screw Pump with Pedestal is built for reliability, modular design, and flexible operation. The pedestal ensures the pump’s vertical alignment, reduces mechanical stress on the drive shaft, and simplifies installation in tight or deep areas such as tanks, wells, or filter press sumps.

The Vertical Screw Pump with Pedestal is versatile and suitable for a broad spectrum of industrial and commercial applications due to its self-priming, non-clogging, and low-pulsation flow characteristics.

Sludge and slurry transfer: Ideal for feeding thickened sludge to dewatering systems.

Sediment removal: Efficiently handles grit, sludge, and organic waste.

Filter press feeding: Continuous feeding without pulsation or pressure surges.

Viscous product transfer: Perfect for conveying honey, jam, yogurt, chocolate, sauces, and purees.

Hygienic processes: 316L stainless steel construction ensures sanitary compliance.

CIP/SIP cleaning compatibility: Easy integration into sanitary process lines.

Acids, resins, and polymers: Resistant to corrosion and chemical attack.

Lubricants and oils: Smooth transfer of viscous liquids without aeration.

Dyes, pigments, and coatings: Handles abrasive or particle-filled fluids effectively.

Pulp transfer: Transfers viscous and fibrous materials without clogging.

Additive feeding: Accurate dosing and feeding of chemicals or pigments.

Creams and gels: Gentle pumping action preserves texture and product quality.

Hygienic liquid transfer: Ideal for GMP-compliant processes.

Cement grout and mortar transfer: Durable against abrasive slurries.

Mine dewatering and slurry handling: Handles viscous and particle-rich fluids efficiently.

Proper installation and operation of the Vertical Screw Pump with Pedestal ensure optimal efficiency and long lifespan.

Positioning: Install the pump vertically over the tank or pit so that the suction inlet is submerged in the fluid.

Foundation: Secure the pedestal on a rigid base to prevent vibration and misalignment.

Alignment: Ensure the coupling between the motor and pump shaft is precisely aligned.

Piping: Use flexible couplings or compensators to absorb vibration and prevent stress.

Priming: Fill the suction chamber before startup to prevent dry running.

Start-Up:

Verify direction of rotation.

Start at low speed, especially with viscous or solid-laden fluids.

Gradually increase speed to operating level.

Monitoring:

Observe flow rate, pressure, and temperature.

Check for unusual vibration, noise, or seal leakage.

Feeding Filter Presses or Reactors:

Adjust flow rate using a variable frequency drive (VFD).

Maintain stable feeding to ensure consistent pressure and product quality.

Shutdown:

Stop the pump and flush with cleaning solution or water (especially for sticky materials).

Drain residual fluid from the system.

Lubrication: Regularly lubricate bearings and mechanical seals.

Inspection: Check rotor, stator, and seals for wear after each operating cycle.

Seal Replacement: Replace seals immediately if leakage occurs.

Cleaning: Use CIP systems for sanitary models; flush abrasive or corrosive media after each use.

Storage: When idle for long periods, clean thoroughly and coat metallic parts with anti-rust oil.

Vertical screw pumps save space, are easier to integrate into tanks or pits, and provide better self-draining capability. The pedestal design offers superior stability and ease of maintenance.

Yes, the rotor-stator mechanism ensures smooth, non-pulsating transfer of viscous, abrasive, or solid-laden fluids.

Absolutely. The 316L stainless steel sanitary version meets FDA and EHEDG standards and supports CIP/SIP cleaning.

Mechanical seals, packing seals, or cartridge seals are available depending on the operating conditions and media characteristics.

No, dry running can damage the stator. The pump should always be filled or primed before startup.

Up to 100,000 cP, depending on the configuration and motor power.

Flow can be controlled by adjusting the pump speed using a Variable Frequency Drive (VFD).

Routine inspection should be carried out every 500 operating hours, or as recommended for specific operating conditions.

Yes, materials, seals, drives, and mounting configurations can all be customized to meet application-specific requirements.

Compact Design: Saves floor space and simplifies installation.

Stable Operation: Pedestal base reduces vibration and mechanical stress.

Pulsation-Free Flow: Ensures steady transfer of viscous and shear-sensitive fluids.

Versatile Application: Suitable for wastewater, chemical, food, and pharmaceutical industries.

Low Maintenance: Modular design and accessible components simplify servicing.

Material Flexibility: Available in various materials to handle corrosive or abrasive media.

Quiet Operation: Smooth mechanical motion minimizes vibration and noise.

Energy Efficient: High volumetric efficiency reduces power consumption.

Long Service Life: Wear-resistant components ensure durability even under demanding conditions.

Customizable Options: Choice of drives, seals, and materials for different environments.

The Vertical Screw Pump with Pedestal is an advanced, efficient, and space-saving solution for viscous, abrasive, and shear-sensitive fluids. Its vertical configuration and pedestal support ensure maximum stability, compact installation, and minimal maintenance requirements.

Engineered for industrial-grade performance, it is widely used across wastewater treatment, food processing, chemical, and pharmaceutical industries, offering pulsation-free operation, low noise, and long service life.

With a modular design, customizable materials, and energy-efficient operation, this pump meets the needs of modern fluid handling systems requiring precision, reliability, and hygiene.

Whether installed as a sludge transfer unit, filter press feeder, or food-grade vertical pump, the Vertical Screw Pump with Pedestal delivers consistent performance, superior durability, and simplified maintenance — making it a trusted choice for demanding industrial environments.

Copyright ? Jiangsu Longjie Pump Manufacturing Co., Ltd.