Features of stainless steel thick slurry pumps:

1. Variable displacement; displacement is proportional to speed, adjustable via a variable speed drive or variable speed motor.

2. Strong self-priming capability and excellent suction performance; no water inlet or check valves are required for direct liquid suction.

3. Capable of pumping all media with high concentrations, high viscosities, and water content, including liquids containing fibers and solid particles, with a high concentration ratio of up to 40% by weight.

4. Maintains high discharge pressure even at low flow rates, independent of speed.

5. Stable liquid delivery, no overflow, agitation, or pulsation. No structure that inhibits condensation of liquids, resulting in low noise levels. Stable, foam-free delivery makes it particularly suitable for shear-sensitive media.

6. The pump is reversible and can deliver in reverse. Liquid flow direction can be changed by the direction of pump rotation, making it suitable for pipeline backwashing.

7. Air in the suction port does not affect pumping, making it suitable for liquids containing gas.

8. Simple structure, easy assembly and disassembly.

Sanitary thick slurry pumps are suitable for the following industries:

1. Food Industry: Transporting minced meat, potato salad, sauces, concentrated juices, jams, and vegetable products.

2. Brewing Industry: Transporting distiller's grains, yeast, various fermentation residues, and other ingredients.

3. Sugar Industry: Transporting syrups, saturated residues, concentrated wastewater residues, sugar-containing crystallized pastes, milk, and cheese.

4. Textile Industry: Transporting synthetic fiber liquids, viscose liquids, dyes, inks, and nylon powder liquids.

5. Paper Industry: Transporting paper pulp, talc slurries, and glazing resin slurries.

6. Petroleum Industry: Transporting various oils, grease products, refinery sludge, and industrial wastewater.

7. Chemical Industry: Transporting various latexes, suspensions, ointments, shampoos, paints, and pigments.

8. Construction Industry: Transporting mortar, plaster, asphalt, tar, mud slurries, and coatings.

9. Mining Industry: Transporting oxides and wastewater, mine drainage, liquids, and scum.

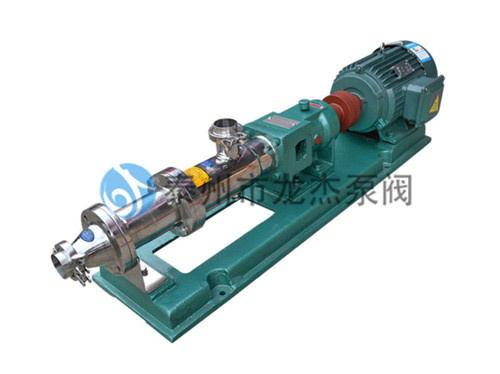

The Stainless Steel Thick Slurry Pump—also known as a Food Grade Thick Slurry Pump or Honey Transfer Pump—is a high-efficiency, hygienic pumping solution specifically designed for viscous, semi-solid, and particulate-rich materials. Engineered with progressive cavity (screw) or lobe technology, it delivers smooth, pulsation-free flow while maintaining the integrity and quality of sensitive materials.

Made entirely from premium stainless steel (304 or 316L), this pump meets the highest sanitary and corrosion-resistant standards, making it ideal for applications in the food, beverage, cosmetic, chemical, and pharmaceutical industries.

The Thick Slurry Pump is designed to handle materials that are too viscous for centrifugal pumps—including pastes, slurries, creams, honey, and concentrated fruit pulps. The pump can easily handle fluids with viscosity ranging from 1,000 cP to over 1,000,000 cP, maintaining stable pressure and consistent output.

Its low-shear operation ensures that fragile or shear-sensitive products (like yogurt, honey, or emulsions) are transferred without separation or damage. The modular structure allows easy cleaning, disassembly, and maintenance—fully compliant with CIP (Clean-In-Place) and SIP (Sterilize-In-Place) standards.

All-Stainless-Steel Construction – Manufactured using SS304 or SS316L for excellent corrosion resistance and hygiene.

High Viscosity Handling – Capable of transferring slurries, pastes, and sticky fluids without blockage or cavitation.

Food-Grade Design – Smooth internal surfaces minimize contamination and ensure easy cleaning.

Low Shear, Gentle Pumping – Protects texture, taste, and integrity of delicate materials.

Pulsation-Free Flow – Progressive cavity or lobe pumping action ensures uniform discharge.

Wide Flow Range – From small dosing systems to large-volume transfer applications.

Self-Priming and Reversible Flow – Can operate in either direction for filling or emptying.

CIP/SIP Compatibility – Fully compliant with sanitary plant cleaning systems.

High Efficiency and Quiet Operation – Low noise and minimal vibration design.

Customizable Sealing Options – Mechanical seals, double mechanical seals, or packing seals available.

Portable or Fixed Installation – Available with mobile trolleys or stationary base mounts.

Optional Heating Jacket – Keeps materials like honey or fats at desired transfer temperature.

| Parameter | Specification |

Model Name | Stainless Steel Thick Slurry Pump |

Pump Type | Progressive Cavity / Rotary Lobe / Screw Type |

Flow Range | 0.05 – 60 m3/h |

Pressure Range | Up to 1.2 MPa |

Viscosity Handling | 1,000 – 1,000,000 cP |

Material of Construction | Stainless Steel 304 / 316L |

Stator Material | NBR, EPDM, FKM, Silicone Rubber |

Rotor Material | Hardened SS / Chrome-Plated Steel |

Seal Type | Single Mechanical Seal / Double Mechanical Seal / Packing Seal |

Drive Options | Electric Motor / VFD / Gear Motor / Pneumatic Motor |

Speed Range | 100 – 1,500 rpm (adjustable) |

Temperature Range | -20°C to +120°C (optional up to 150°C) |

Inlet / Outlet Size | DN25 – DN100 (customizable) |

Mounting Style | Vertical / Horizontal / Mobile Trolley |

Power Range | 0.55 – 15 kW |

Compliance | CE / ISO 9001 / FDA / 3A Sanitary Standard |

Noise Level | ≤70 dB(A) |

Cleaning System | Manual / CIP / SIP Compatible |

The Stainless Steel Thick Slurry Pump is highly versatile. Its gentle yet powerful operation makes it suitable for a wide variety of industries and applications that involve high-viscosity or semi-solid products.

Honey and Syrup Transfer: Maintains natural flavor and prevents crystallization.

Tomato Paste, Ketchup, and Jam: Handles sticky, thick materials without foaming.

Chocolate, Cream, and Dairy Products: Transfers high-fat materials with temperature stability.

Sauces and Concentrates: Preserves product consistency and texture.

Beverage Concentrates: Pumps fruit pulp or sugar syrup mixtures efficiently.

Ointments and Creams: Transfers viscous pharmaceutical bases without contamination.

Gels and Suspensions: Maintains particle uniformity.

Syrups and Extracts: Gentle flow avoids bubble formation and oxidation.

Fermentation Liquids and Enzyme Solutions: Hygienic transfer suitable for sterile environments.

Lotions, Shampoos, and Conditioners: Smooth and low-shear transfer of thick emulsions.

Toothpaste and Gel: Precise and clean delivery for batch processing.

Essential Oils and Creams: Maintains aroma and emulsion stability.

Resins, Adhesives, and Sealants: Handles high-viscosity, non-Newtonian materials.

Lubricants, Grease, and Oil: Consistent output for blending or filling systems.

Paints, Dyes, and Pigments: Prevents shear degradation and ensures uniform distribution.

Ceramic Slurries and Polishing Compounds: Stable pumping for high-density materials.

Pure Honey Pumping: Keeps honey’s natural enzymes and nutrients intact.

Temperature-Controlled Honey Transfer: Optional heating jacket keeps honey liquid even in cold environments.

Food-Grade Stainless Steel: Guarantees no contamination or flavor alteration.

Portable Honey Pump System: Allows easy transfer between containers, drums, and bottling lines.

Sludge and Slurry Transfer: Handles thickened sludge and flocculant solutions.

Bio-Waste Pumping: Effective for organic waste in food processing plants.

Oil-Water Separation Units: Pumps oily waste mixtures efficiently.

Copyright ? Jiangsu Longjie Pump Manufacturing Co., Ltd.