1. Overview of Sludge Screw Pumps (Thick Slurry Pumps)

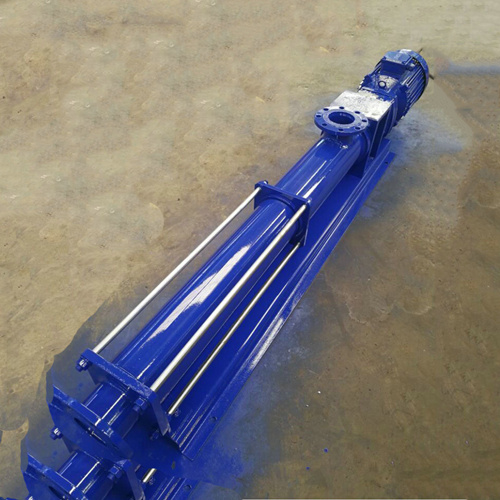

A sludge screw pump is a thick slurry pump. Its main working components are an eccentric helical screw (i.e., rotor) and a screw bushing (i.e., stator) with a double-helical inner surface.

A sludge screw pump is a specific application of a single screw pump for sludge and wastewater treatment. This pump utilizes an eccentric single-helix screw rotating within a double-helix bushing, pushing sludge and wastewater along the spiral grooves from the suction port to the discharge port. This is the operating principle of a sludge screw pump.

2. Working Principle of a Sludge Screw Pump (Thick Slurry Pump)

A sludge screw pump is a single-screw conveying pump. Its main working components are an eccentric helical screw (called the rotor) and a screw bushing (called the stator) with a double-helical inner surface. Its operating principle is that when the motor drives the pump shaft, the screw rotates around its own axis while rolling along the inner surface of the bushing, thus forming a sealed chamber in the pump. With each revolution of the screw, the liquid in the sealed chamber is pushed forward one pitch. As the screw continues to rotate, the liquid is pressed spirally from one sealed chamber to the other, ultimately squeezing out of the pump body. A screw pump is a new type of liquid conveying machine, characterized by a simple structure, safe and reliable operation, easy use and maintenance, continuous and uniform liquid discharge, and stable pressure.

A sludge screw pump uses the rotation of the screw to pump and discharge liquids, making it ideal for pumping and discharging viscous liquids.

3. Advantages of Sludge Screw Pumps (Thick Slurry Pumps)

Sludge screw pumps, also known as single screw pumps, possess the common advantages of screw pumps. They are suitable for conveying low-viscosity media such as water, as well as suspensions containing solid particles or short fibers, and very high-viscosity media.

1) Wide pressure and flow range. Pressures range from approximately 3.4 to 340 kgf/cm2, with flow rates up to 18,600 cm3/min.

2) A wide range of liquid types and viscosities can be transported.

3) Because the rotating components within the sludge screw pump have low inertia, they can operate at very high speeds.

4) Excellent suction performance and self-priming capability.

5) Uniform and continuous flow, low vibration, and low noise.

6) Less sensitive to incoming gas and contaminants than other rotary pumps.

7) Robust construction and easy installation and maintenance.

4. Sludge Screw Pump (Thick Slurry Pump) Applications

Thick slurry pumps are positive displacement pumps with rotors made of stainless steel or 40 chrome and stators made of medium-hardness rubber. Therefore, these pumps are ideal for conveying thick media containing solid particles, such as those used in sludge and sewage treatment industries. For example:

1. Transporting molasses, sugar syrup, dregs, and beet pulp in sugar refineries;

2. Loading and transporting milk powder, starch, honey, coffee, milk, cream, cooking oil, various vitamin solutions, maltose, ketchup, jam, mayonnaise, ice cream, etc. in canneries and food factories;

3. Feeding and dosing alcoholic beverages, spices, and fermentation broth in wineries, and transporting grain waste for filter presses;

4. Transporting cod liver oil, fish oil, fish floss, and fish waste in fish processing plants;

5. Transporting sugar syrup and fruit juice, mashing citrus fruits, and feeding stuffing machines in fruit processing plants;

6. Loading and transporting cooking oil, rice, and corn starch in grain and oil processing plants;

7. Meat processing plants and butcheries; extracting, packaging, and transporting waste liquids;

8. Pharmaceutical factories: Feeding and transporting various vitamin solutions, liquid medicines, and emulsions; transporting suspensions, brine, salt sludge, and pharmaceutical residues;

9. Chemical industry: Transporting acids and alkalis; feeding, batching, and transporting various suspensions, oils, glues, various chemical dyes, paints, adhesives, ointments, and slurries. This pump can especially transport high-viscosity materials or materials containing solid particles that are difficult for conventional centrifugal pumps to transport;

10. Batching and transporting inks;

11. Transporting pulp and ink in paper mills;

12. Transporting oil products, oils, waste liquids, and sludge in petrochemical plants;

13. Transporting calcium carbide sludge in acetylene plants;

14. Transporting mortar, lime milk, mortar, and cement slurry in the construction industry;

15. Can be used in conjunction with pumping, and transporting and loading materials in feed processing;

16. Widely used for industrial and domestic sewage and sludge treatment. Sewage typically contains a high level of suspended matter, is corrosive, and has a high viscosity, often containing solid particles. Therefore, a thick slurry pump is suitable for transporting it.

17. Used for transporting contaminated water, contaminated liquids, and other materials at nuclear power plants.

18. Used for mine sewage and sludge.

5. Sludge Screw Pump (Thick Slurry Pump) User Guide

Sludge Screw Pump Startup

1. Prepare the necessary wrenches and tools.

2. Check the base, bearings, and oil chamber for lubricant.

3. Check the hollow shaft for proper sealing. Do not overtighten the packing gland; allow for dripping.

4. Turn the coupling by hand or with a pipe wrench. Check for any foreign objects in the pump body, making noise or causing any jamming. Remove any debris before starting the pump.

5. Fill the pump chamber with liquid. Avoid friction to prevent the ball bushing from being damaged.

6. Fully open the gate valve on the liquid outlet pipe. 7. Start the motor.

Shutting down the sludge screw pump

1. Close the suction pipe valve.

2. Close the discharge pipe valve.

3. Stop the motor.

4. When the pump is shut down for an extended period, drain the pump chamber and flush with water or steam.

Operating the sludge screw pump

1. Regularly check the temperature rise of the pump and motor bearings. The maximum temperature should not exceed 75°C.

2. Refill lubricating oil promptly to ensure proper bearing lubrication.

3. During operation, if any abnormal noise or excessive vibration is detected, immediately stop the pump and inspect to correct the problem.

4. If the flow rate decreases significantly, the rubber lining is worn and should be replaced before operation.

Copyright ? Jiangsu Longjie Pump Manufacturing Co., Ltd.