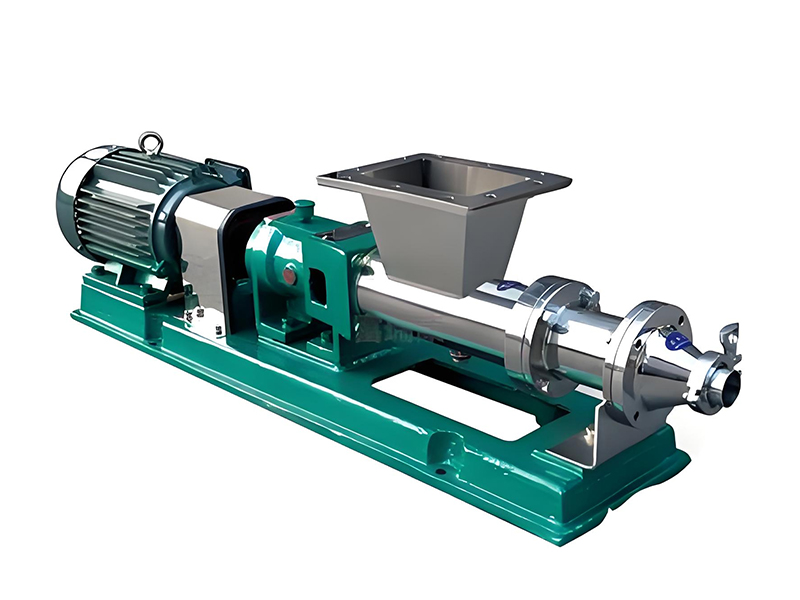

This thick slurry pump is a single-rod screw pump (also known as a screw pump), a new, advanced pump designed in my country. Its notable features include a simple structure, stable operation, easy operation, and adaptability to any location.

It is suitable for conveying high-viscosity media, and is particularly popular in chemical plants, breweries, food factories, paper mills, canning factories, pharmaceutical factories, and distilleries. Consequently, this pump has been widely adopted by industrial and mining enterprises and research institutions nationwide, achieving excellent results.

This thick slurry pump is a single-screw pump. Its main working components are an eccentric helical screw (called a rotor) and a screw bushing (called a stator) with a double-helical inner surface.

All metal parts in the thick slurry pump that come into contact with the material are made of high-quality stainless steel, and the liner is made of non-toxic and odorless, reliable rubber. Operating at temperatures up to 100°C, it can be used to convey food slurries and corrosive media with viscosities ranging from 1 to 1,000,000 centipoise, including solutions, slurries, and suspensions containing solid particles or colloids.

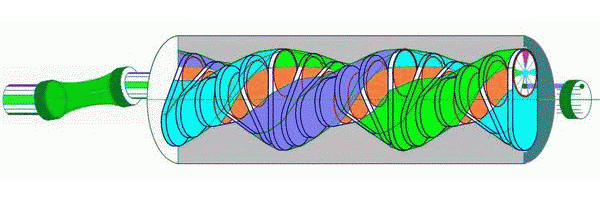

Working Principle of the GNF Thick Slurry Pump:

When the motor drives the pump shaft, the screw rotates around its own axis while rolling along the inner surface of the bushing, forming the pump's sealed chamber. With each revolution of the screw, the liquid in the sealed chamber advances one screw pitch. As the screw continues to rotate, the liquid spirals from one sealed chamber to the other, ultimately being squeezed out of the pump body.

Copyright ? Jiangsu Longjie Pump Manufacturing Co., Ltd.