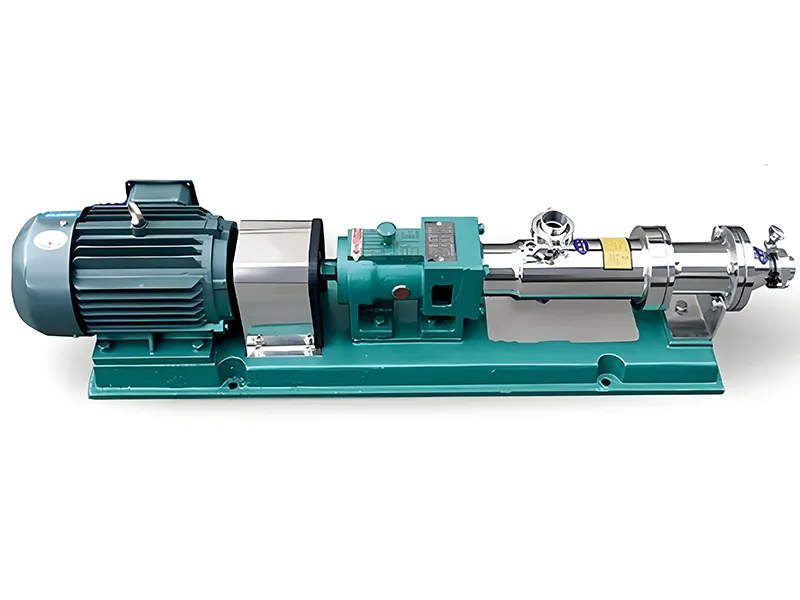

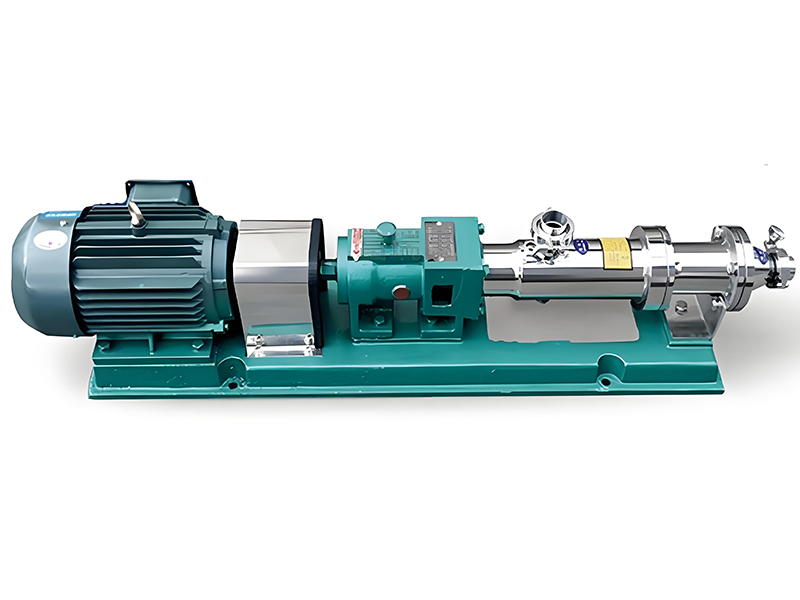

The Single-Stage Stainless Steel Screw Pump is a precision-engineered positive displacement pump specifically designed for the transfer of viscous, abrasive, and particulate-laden materials in industries such as food processing, cosmetics, pharmaceuticals, and chemicals. Constructed from high-grade stainless steel (304 or 316L), this pump ensures exceptional corrosion resistance, hygiene, and durability, making it ideal for sanitary and industrial fluid transfer applications.

Unlike centrifugal pumps that rely on high-speed impellers, a screw pump employs a rotor-stator mechanism to generate continuous flow with minimal pulsation. The single-stage design simplifies structure, reduces maintenance, and provides steady flow output even under fluctuating pressures.

The pump’s self-priming capability, gentle conveying action, and ability to handle high-viscosity or solid-containing fluids make it a preferred solution across multiple industries.

The pump is composed of a rotor, stator, drive shaft, mechanical seal, and housing assembly. Its progressive cavity principle enables precise volumetric flow, while stainless steel components ensure compatibility with a wide range of fluids.

Rotor: Typically made of hardened stainless steel, precision-machined with helical geometry to form the pumping cavities.

Stator: Composed of food-grade elastomer (NBR, EPDM, or FKM) tightly fitted within a stainless steel casing. The elastomer provides sealing between the cavities, enabling smooth fluid transfer.

The pump employs mechanical seals or lip seals to prevent leakage during operation.

Bearings and coupling shafts are engineered to withstand radial and axial loads, ensuring long-term stability under high torque.

The single-stage stainless steel screw pump supports various drive configurations:

Direct drive via electric motor

Geared reducer drive for adjustable speed

Frequency converter control for variable flow output

Smooth, polished stainless steel surfaces minimize residue accumulation.

CIP (Clean-in-Place) and SIP (Steam-in-Place) compatible.

Detachable components for easy disassembly and maintenance.

| Model | Flow Range (m3/h) | Pressure (MPa) | Speed (rpm) | Viscosity Range (mPa·s) | Material (Body/Rotors) | Temperature Range (°C) |

G1-15 SS316L | 0.1 – 2.5 | 0.6 | 400–900 | 1–100,000 | SS316L / NBR | -10 to 100 |

G1-25 SS316L | 0.5 – 5.0 | 0.6 | 400–900 | 1–150,000 | SS316L / EPDM | -10 to 120 |

G1-40 SS316L | 1.0 – 10.0 | 0.6 | 350–800 | 1–200,000 | SS316L / FKM | -10 to 150 |

G1-50 SS316L | 2.0 – 20.0 | 0.6 | 300–700 | 1–300,000 | SS316L / NBR | -10 to 100 |

Customization available for higher viscosity, higher pressure, or food-grade and pharmaceutical-grade standards. The pump can be configured with heating jackets, hopper inlets, or pressure sensors depending on process requirements.

The Single-Stage Screw Pump operates based on the progressive cavity principle, where the rotor turns eccentrically inside the stator. This movement forms a series of sealed cavities that move from the suction side to the discharge side, carrying fluid gently and continuously.

This mechanism:

Provides uniform, pulsation-free flow

Handles high-viscosity or shear-sensitive materials

Ensures minimal damage to suspended solids or delicate ingredients

Offers self-priming and reverse pumping capabilities

Compared to centrifugal pumps, screw pumps maintain constant flow rates independent of viscosity changes, making them ideal for food pastes, slurries, emulsions, creams, and sauces.

Tomato paste, honey, yogurt, syrup, molasses, peanut butter

Meat emulsions, fruit pulps, salad dressings

Ensures hygiene with 316L stainless steel and sanitary-grade seals

Suitable for CIP/SIP cleaning without disassembly

Transfer of creams, lotions, shampoos, gels, toothpaste

Gentle handling prevents product aeration or structural degradation

Ideal for ointments, suspensions, gels, and liquid medicines

Supports GMP-compliant production with full traceability and sterilization options

Polymers, resins, lubricants, and adhesives

Handles both Newtonian and non-Newtonian fluids

Resistant to corrosion and high temperatures

Can transport sludge, slurry, and bio-waste in treatment plants

Smooth and non-clogging flow path reduces downtime

High Efficiency and Energy Saving – Maintains flow regardless of viscosity with low energy input.

Gentle Conveying Action – Prevents product degradation in sensitive fluids.

Hygienic Design – Full stainless steel structure for easy cleaning.

Wide Viscosity Range – From thin liquids to pastes exceeding 1,000,000 mPa·s.

Low Pulsation and Noise – Stable continuous flow.

Customizable Options – Heating jacket, pressure relief, variable speed control.

Self-Priming Capability – Can draw liquid even when dry at startup.

Reversible Operation – Enables bidirectional flow when required.

Ensure the pump is mounted horizontally or vertically on a firm, vibration-free base.

Align the drive motor and coupling precisely to avoid bearing wear.

Install flexible hoses or expansion joints to minimize stress.

Verify that all valves are open and suction lines are filled.

Start the motor at low speed to confirm normal operation.

Gradually increase to rated speed.

Avoid dry running for more than 30 seconds.

Maintain steady inlet supply; air entrainment may reduce efficiency.

Monitor temperature and vibration levels during operation.

Periodically check seals and elastomer stator for wear.

Regularly lubricate bearings and inspect coupling alignment.

Replace stator or mechanical seal if leakage or performance drop occurs.

Clean with CIP solutions appropriate for the product (e.g., hot water, caustic soda).

Use protective guards over rotating shafts.

Do not exceed rated pressure or temperature limits.

Follow local safety standards and electrical codes.

| Problem | Possible Cause | Solution |

No flow or low flow | Air trapped, suction line blocked | Prime the pump, clean suction line |

Excessive vibration | Misalignment, worn bearings | Realign components, replace bearings |

Leakage at seal | Seal worn or dry run | Replace mechanical seal, check lubrication |

Overheating | Dry running, high viscosity | Reduce speed, ensure proper feeding |

Reduced capacity | Stator wear | Replace stator and check fluid compatibility |

Noise | Cavitation or imbalance | Check suction pressure, realign pump |

Flush the pump with warm water or cleaning solution after every production batch.

For food applications, use CIP cycles at 80–90°C followed by sterile rinse.

Apply food-grade lubricants on seals and couplings.

Periodically dismantle and inspect internal components for wear or residue buildup.

CE / ISO9001 / FDA / 3A Sanitary Standard

Compliant with EHEDG (European Hygienic Engineering & Design Group) guidelines

Optional ATEX certification for explosive environments

Material choices: SS304, SS316, SS316L, duplex stainless steel

Seal types: mechanical seal, double mechanical seal, gland packing

Drive systems: direct, geared, variable frequency

Mounting options: base-mounted, mobile trolley, wall or vertical configuration

The Single-Stage Stainless Steel Screw Pump offers a robust, hygienic, and energy-efficient solution for transferring viscous, abrasive, or solid-laden fluids. With its modular design, gentle pumping action, and sanitary-grade materials, it is ideally suited for the food, beverage, cosmetic, and pharmaceutical industries.

Whether you are processing thick sauces, dairy pastes, or cosmetic gels, this screw pump delivers reliable performance, long service life, and easy maintenance — ensuring a smooth and contamination-free production process.

Copyright ? Jiangsu Longjie Pump Manufacturing Co., Ltd.