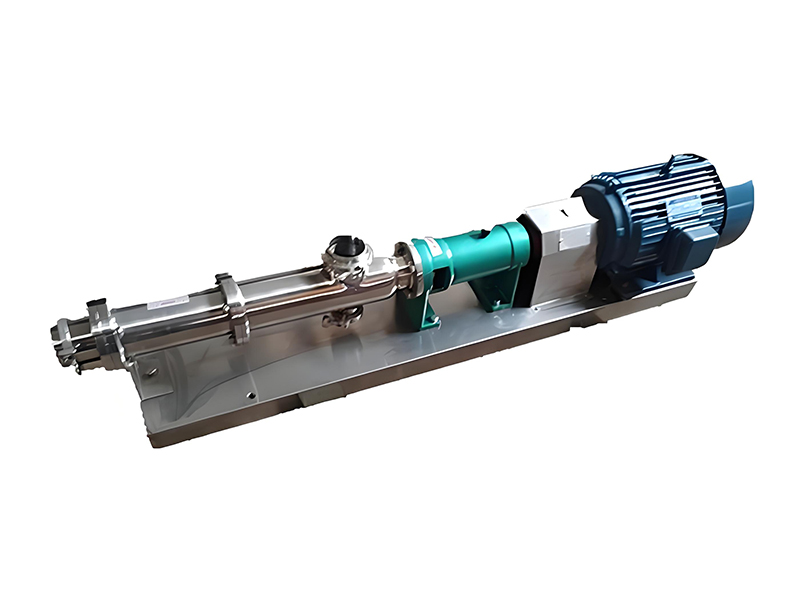

The Small Stainless Steel Screw Pump, also known as the 304 screw pump, is a compact, food-grade positive displacement pump designed to handle viscous, particle-laden, or delicate fluids in a wide variety of food and beverage processing applications. Engineered with precision and durability in mind, this pump combines stainless steel construction, low-shear conveying, and smooth, continuous flow, making it ideal for transferring products like sauces, syrups, jams, honey, and dairy concentrates.

Constructed entirely from 304 stainless steel, the pump offers excellent corrosion resistance, sanitary performance, and ease of cleaning. It can be integrated into both small and large-scale production systems, offering flexibility for batch processing, continuous transfer, or metered dosing.

As a progressive cavity screw pump, it uses a rotor and stator assembly to gently convey material through a sequence of sealed cavities, ensuring steady output without pulsation or turbulence. Its small footprint, quiet operation, and hygienic design make it particularly suitable for food factories, laboratories, pilot plants, and small-scale beverage production lines.

The small stainless steel screw pump operates on the progressive cavity principle, where a single helical rotor turns eccentrically inside a double helical stator made from food-grade elastomer. This creates a series of sealed cavities that move the liquid forward as the rotor turns, ensuring continuous, low-pulsation flow.

The pump’s compact body and precisely machined components ensure stable flow output and efficient suction, even with high-viscosity materials. Compared with centrifugal pumps, the screw pump maintains consistent flow independent of viscosity or pressure changes.

Pump Body (Casing):

Made from 304 stainless steel, the body provides corrosion resistance and structural strength, suitable for both acidic and alkaline food media.

Rotor:

Precision-machined from hardened stainless steel. It forms the pumping cavity and provides consistent flow performance.

Stator:

Fabricated from NBR (Nitrile Rubber), EPDM, or FKM, the stator elastomer ensures a tight seal and smooth transfer, compatible with a wide range of food materials.

Shaft Seal:

Mechanical seal or lip seal to prevent leakage during operation. Food-grade materials ensure compliance with FDA and hygienic standards.

Drive Unit:

The pump can be powered by a direct motor drive, gear reducer, or variable frequency inverter, allowing adjustable speed control and flow rate precision.

Mounting Configuration:

Available in horizontal, vertical, or portable trolley-mounted forms for flexible installation in compact spaces.

| Model | Flow Rate (L/h) | Pressure (MPa) | Speed (rpm) | Viscosity Range (mPa·s) | Material (Body/Rotors) | Temperature Range (°C) |

G10-1 SS304 | 50 – 300 | 0.6 | 400 – 900 | 1 – 50,000 | SS304 / NBR | -10 to 90 |

G15-1 SS304 | 200 – 800 | 0.6 | 400 – 900 | 1 – 100,000 | SS304 / EPDM | -10 to 120 |

G20-1 SS304 | 300 – 1200 | 0.6 | 350 – 800 | 1 – 200,000 | SS304 / FKM | -10 to 130 |

G25-1 SS304 | 500 – 1800 | 0.6 | 300 – 700 | 1 – 300,000 | SS304 / NBR | -10 to 100 |

Optional configurations:

Heating jacket for maintaining temperature-sensitive materials

Hopper feed for paste-like or semi-solid foods

Variable speed control for precise metering

Quick-disassembly design for rapid cleaning and maintenance

All wetted parts are made from food-grade 304 stainless steel, polished to a mirror finish to prevent material buildup and microbial growth.

Complies with FDA and 3A sanitary standards for food contact equipment.

The progressive cavity design provides low-shear, laminar flow, preserving product structure and consistency. Ideal for fragile or aeration-sensitive products such as cream, yogurt, or fruit puree.

Designed for limited-space installations, mobile setups, and small production units. Despite its small size, it maintains robust flow and pressure capabilities.

Provides pulsation-free transfer even with highly viscous fluids, ensuring stable feeding into mixers, filters, and filling systems.

Handles a wide range of fluid properties:

Thin liquids (milk, juice)

Thick pastes (tomato paste, peanut butter)

Semi-solids (minced fruit, chocolate)

Simple rotor-stator replacement

Quick disassembly design for sanitation

CIP/SIP compatible for automated cleaning

Compared to pneumatic or gear pumps, screw pumps offer lower energy consumption for the same volume transfer, making them both eco-friendly and cost-effective.

The small stainless steel screw pump is particularly suited for:

Viscous liquids: honey, molasses, syrup, condensed milk

Semi-solid materials: jam, fruit paste, peanut butter

Fermented products: yogurt, cheese slurry

Liquid mixtures: salad dressings, sauces, purees

It is frequently used in:

Small-scale filling lines

Pilot or test production

Ingredient dosing

Batch transfer between tanks

Ideal for conveying cream, curd, butter, and milk concentrate with minimal air inclusion. Maintains product integrity and texture through gentle conveying.

Used for transferring chocolate, dough pastes, icing, syrups, and fillings without clogging or overheating.

Can handle fruit juice concentrate, beer yeast, or malt extracts. The pump’s sanitary design ensures purity and taste preservation.

Suitable for creams, gels, lotions, and ointments requiring hygienic and non-destructive handling.

Mount the pump horizontally on a flat surface.

Ensure proper alignment between pump and motor couplings.

Install flexible connections on suction and discharge to prevent vibration transmission.

Provide a clean, dry, and stable power source.

Fill the suction pipe with fluid before starting (avoid dry running).

Start the pump at low speed, gradually increasing to operating speed.

Check for leaks, vibration, and abnormal noise.

Monitor pressure gauges to ensure within design limits.

Maintain steady inlet supply and temperature.

Avoid running the pump dry as it may damage the stator.

For viscous or sticky materials, use preheating or jacketed versions.

Adjust speed with inverter control for flow regulation.

Stop the pump and close discharge valves.

Flush with warm water or cleaning fluid.

Disconnect power and clean external surfaces.

Flush the pump after each batch using CIP cleaning solution (80°C water or alkaline detergent).

Ensure cleaning fluid passes through suction and discharge lines completely.

| Component | Inspection Frequency | Action |

Rotor & Stator | Every 3–6 months | Check wear, replace if performance drops |

Seals | Every 2–3 months | Inspect for leakage or cracking |

Bearings | Every 6 months | Lubricate or replace as needed |

Motor Coupling | Every 6 months | Check for alignment and wear |

Tip: Always use food-grade lubricants for parts in contact with the product.

| Issue | Possible Cause | Solution |

No suction | Airlock or dry run | Prime the pump or fill suction line |

Low flow rate | Worn stator or high viscosity | Replace stator or increase temperature |

Leakage at seal | Seal wear or excessive pressure | Replace seal, adjust system pressure |

Overheating | Dry running or excessive speed | Reduce speed, ensure fluid presence |

Noise or vibration | Misalignment | Re-align motor and pump |

Pulsation | Air in fluid | Eliminate air pockets, ensure proper priming |

Never operate the pump without fluid inside.

Do not exceed rated pressure or speed.

Ensure all guards are in place before operation.

Use personal protective equipment (PPE) during maintenance.

Follow local electrical and hygiene safety standards.

Material: SUS304 / Food-grade elastomers (FDA certified)

Standards: CE, ISO9001, 3A Sanitary

Compliance: Meets European Hygienic Engineering & Design Group (EHEDG) guidelines

Options: ATEX certification for explosion-proof environments

| Option | Description |

Material | Upgrade to SS316 or SS316L for higher corrosion resistance |

Seal Type | Mechanical seal, double mechanical seal, or gland packing |

Drive Mode | Direct coupling, gear reducer, or inverter control |

Mounting Type | Horizontal, vertical, or trolley-mounted |

Accessories | Hopper feed, heating jacket, pressure sensor, flow meter |

Compact and portable – fits in tight production spaces

Hygienic and easy to clean – polished 304 stainless steel surfaces

Handles a wide viscosity range – from water to peanut butter

Stable, pulsation-free flow – perfect for precision dosing

Quiet and energy-efficient operation

Customizable configurations for specific processes

Q1. What is the maximum viscosity the small 304 screw pump can handle?

A1. It can handle viscosities up to 300,000 mPa·s, depending on speed and pressure settings.

Q2. Is this pump suitable for CIP and SIP systems?

A2. Yes, all wetted parts are designed for CIP/SIP cleaning, making it ideal for food-grade processes.

Q3. Can the pump transfer products with small particles?

A3. Yes, the gentle conveying principle allows handling of particles (up to 5 mm) without damaging them.

Q4. What temperature range is supported?

A4. Standard models handle -10°C to 100°C, with high-temperature versions available up to 130°C.

Q5. Can I use the pump for honey or syrup transfer?

A5. Absolutely. It’s specifically designed for viscous, sticky liquids like honey, molasses, and syrups.

Q6. How often should I replace the stator?

A6. With proper cleaning, the stator can last 6–12 months depending on usage frequency and medium.

Q7. Does it support variable flow control?

A7. Yes, with frequency converter or gear reduction control, flow can be precisely adjusted.

Copyright ? Jiangsu Longjie Pump Manufacturing Co., Ltd.