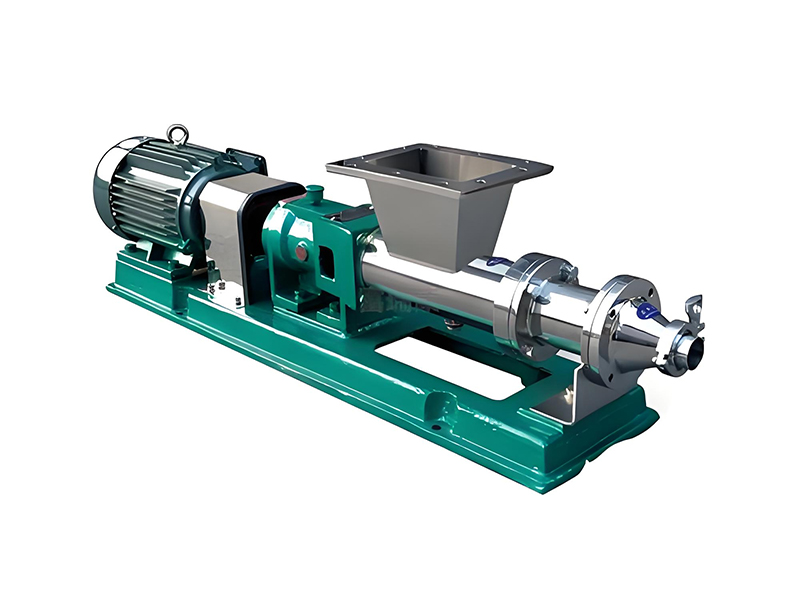

The G-Type Food-Grade Stainless Steel Screw Pump (316L) is a high-precision Progressive cavity pump designed specifically for transferring viscous, semi-solid, and shear-sensitive food products. Constructed entirely from 316L stainless steel, this Hygienic Screw Pump ensures corrosion resistance, smooth flow, and easy cleanability — meeting the strict sanitary requirements of modern food production lines.

This pump is widely used in dairy, beverage, confectionery, and sauce manufacturing, where gentle handling of fluids is critical to preserving product quality, texture, and taste. It operates on the progressive cavity principle, where a helical rotor rotates inside a food-grade elastomer stator, forming continuous sealed cavities that move the medium with a steady, low-pulsation flow.

Unlike centrifugal or gear pumps, the G-Type Screw Pump transfers fluids without turbulence or excessive shear, preventing air entrainment and maintaining product integrity. Its robust 316L stainless steel construction makes it ideal for processing acidic, sugary, or high-viscosity food ingredients such as honey, chocolate, syrup, and condensed milk.

The pump’s modular design supports CIP (Clean-in-Place) and SIP (Sterilization-in-Place) processes, ensuring complete hygiene and compliance with FDA, 3A, and EHEDG standards for food-grade equipment.

316L Stainless Steel Construction

All wetted parts are made from 316L stainless steel, providing superior resistance to corrosion and contamination — suitable for acidic, salty, or sugar-rich environments.

Food-Grade Elastomer Stator

Available in FDA-approved NBR, EPDM, or Silicone Rubber, ensuring safe contact with edible materials.

Gentle and Non-Pulsating Transfer

The progressive cavity design minimizes shear forces and air entrapment, ideal for shear-sensitive or particulate-rich products like fruit puree or yogurt.

Hygienic Design with CIP/SIP Compatibility

Fully polished internal surfaces and sanitary clamp connections ensure easy cleaning and sterilization without disassembly.

Low Noise and Energy Efficient

Smooth, steady pumping action provides quiet operation and reduces power consumption compared to traditional pumps.

Customizable Flow and Pressure Range

Available in various sizes and configurations to match specific process requirements for viscosity, capacity, and head pressure.

Reversible Operation

Allows bi-directional transfer for flexible system integration in filling, recirculation, or emptying processes.

Modular and Easy Maintenance

Quick-access design allows fast rotor/stator replacement and minimal downtime during production cycles.

| Parameter | Specification |

Model | G-Type Food-Grade Stainless Steel Screw Pump (316L) |

Flow Range | 0.05 – 100 m3/h (customized) |

Pressure Range | Up to 1.2 MPa |

Maximum Viscosity | 1,000,000 cP |

Pump Material | 316L Stainless Steel |

Rotor Material | 316L Stainless Steel, Chrome-Plated Alloy |

Stator Material | NBR, EPDM, FKM, or Silicone Rubber (FDA Grade) |

Seal Type | Single/Double Mechanical Seal or Hygienic Lip Seal |

Connection Type | Tri-Clamp / Threaded / Flanged |

Temperature Range | -10°C to +120°C |

Motor Type | Standard / Explosion-proof / Variable Frequency |

Drive Options | Direct Coupled / Gear Reducer / VFD Control |

Noise Level | <70 dB(A) |

Cleaning System | CIP/SIP compatible |

Certifications | CE / ISO 9001 / FDA / 3A Sanitary Standards |

The G-Type Food-Grade Screw Pump (316L) serves as a reliable workhorse across diverse food and beverage manufacturing processes that involve viscous, sticky, or particle-laden materials.

Used in the production and transfer of:

Yogurt, cream, butter, and condensed milk

Cheese curd, whey, and flavored milk mixtures

The gentle pumping mechanism prevents air entrainment and maintains texture consistency during transfer to pasteurizers or fillers.

Ideal for handling:

Sugar syrup, glucose, molasses, fruit concentrates

Liquid malt, flavor bases, and beverage mixes

The 316L construction ensures hygienic transfer without caramelization or sugar buildup inside the pump body.

Handles:

Chocolate paste, cocoa butter, caramel, or fondant

Sugar mixtures, creams, or candy fillings

The pump’s low-shear movement prevents crystallization and maintains uniform temperature control during processing.

Used for:

Tomato paste, chili sauce, ketchup, salad dressing, mayonnaise

Mustard, soy sauce, and concentrated flavor bases

The precise metering capability ensures consistent dosing into mixing and filling machines.

Transfers:

Dough mixes, yeast slurry, and sugar cream fillings

Batters, icing, and viscous glazes

Maintains homogeneous texture and prevents material degradation.

Perfect for:

Honey, molasses, or syrup transfer from storage tanks to bottling lines

Ensures gentle flow without introducing bubbles or altering viscosity.

The G-Type screw pump operates on the progressive cavity principle:

The helical rotor rotates eccentrically within a stator made of flexible elastomer.

This creates a series of sealed cavities that move progressively along the pump axis.

As the rotor turns, each cavity transfers the medium smoothly from the suction to the discharge side.

This design delivers a continuous, pulse-free flow, even at high viscosities or low speeds. It’s especially suitable for delicate or particulate materials where mechanical stress must be minimized.

Ensure all components are properly cleaned before assembly.

Mount the pump on a stable, vibration-free base.

Align the motor and pump shafts accurately to avoid mechanical stress.

Connect sanitary-grade piping using tri-clamp fittings.

Ensure the inlet and outlet lines are of appropriate diameter to prevent cavitation.

Check that the pump and pipeline are filled with product or primed liquid.

Verify correct rotation direction (usually clockwise).

Start the pump at low speed to avoid pressure shock.

Gradually increase to operating speed.

Monitor temperature and pressure during operation.

Stop the pump and close valves to prevent backflow.

Flush the pump with warm water or cleaning solution.

If used with sugary or sticky materials, clean immediately after use to prevent crystallization.

The G-Type screw pump is designed for full CIP/SIP compatibility:

Flush with warm water (50–60°C) for sugar-based fluids.

Use food-safe cleaning agents approved for stainless steel.

Rinse thoroughly and drain before restarting production.

Lubricate motor bearings according to manufacturer recommendations.

Inspect stator and rotor for wear — replace if performance drops.

Check mechanical seals for leakage and replace seals when necessary.

Keep the pump and environment free of residue buildup.

| Task | Frequency |

Visual inspection | Daily |

Seal inspection | Weekly |

Rotor/Stator replacement check | Quarterly |

Full CIP/SIP cleaning | After every batch |

Bearing lubrication | Every 500 hours |

| Issue | Cause | Solution |

No flow or low output | Air lock or incorrect rotation | Re-prime the pump, verify direction |

Excessive noise | Dry running or stator damage | Stop immediately, refill, or replace stator |

Leakage at shaft seal | Seal worn or misaligned | Replace or re-adjust mechanical seal |

Reduced efficiency | Stator swollen due to chemical incompatibility | Use proper FDA-approved elastomer |

Overheating | Viscosity too high or suction restriction | Increase inlet pipe size or reduce speed |

Foaming in product | Air entrainment | Check suction fittings and prevent air entry |

Hygienic design compliant with international food standards (3A, FDA)

Consistent product quality — gentle pumping avoids emulsification or foaming

High viscosity handling — suitable for honey, jam, cream, and paste-like materials

Easy disassembly for inspection

Compatible with CIP/SIP systems

Precise dosing control for filling and metering

Stable performance under continuous operation

Custom-built for specific viscosities and flow rates

Never run the pump dry — always ensure liquid is present.

Do not exceed rated pressure and temperature.

Disconnect power before maintenance.

Use only food-grade lubricants for seals and couplings.

Ensure all contact parts are sanitized before production.

Avoid sudden startup with full discharge pressure — use soft-start VFD control.

The G-Type Food-Grade Stainless Steel Screw Pump (316L) represents the next generation of sanitary fluid transfer technology for the food industry. With its 316L stainless steel construction, gentle conveying action, and CIP-compatible design, it ensures consistent product quality, hygiene, and long service life.

Whether handling honey, syrup, chocolate, dairy cream, or fruit concentrate, this pump maintains texture and flavor integrity while providing efficient, low-maintenance operation. Its modular design, wide viscosity handling range, and customizable performance make it an indispensable tool in any modern food processing plant.

From small artisan producers to large-scale manufacturing lines, the G-Type 316L food-grade screw pump provides reliability, hygiene, and performance — ensuring your products reach perfection from tank to table.

Copyright ? Jiangsu Longjie Pump Manufacturing Co., Ltd.