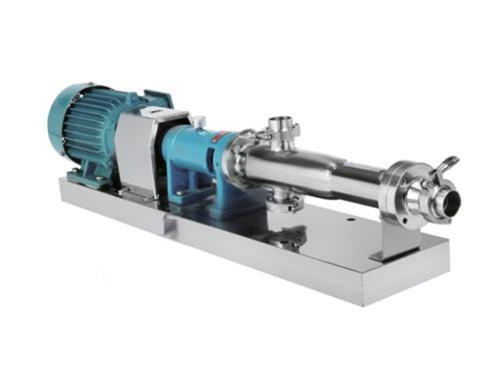

The G-Type Sanitary Screw Pump is a high-performance, precision-engineered pump designed for food, pharmaceutical, cosmetic, and chemical industries. Constructed from 316L stainless steel, it meets stringent sanitary standards and is suitable for handling viscous, shear-sensitive, and delicate fluids without contamination. Its single-screw or twin-screw configuration ensures gentle yet continuous fluid transfer, making it ideal for applications requiring consistent product quality.

The pump features a compact, easy-to-clean design, which simplifies maintenance and reduces downtime. Its seal-less design minimizes leakage risk, ensuring safe handling of hygienic fluids. The G-Type pump combines reliability, efficiency, and sanitary compliance, making it a preferred choice for high-demand processing environments.

The G-Type Sanitary Screw Pump is engineered to provide precision fluid transfer while maintaining hygiene and safety standards. Typical technical specifications include:

| Parameter | Specification |

Pump Type | Single-screw or Twin-screw |

Material | 316L Stainless Steel |

Flow Rate | 0.1–50 m3/h |

Max Pressure | 1.2 MPa (12 bar) |

Max Temperature | 0–120°C |

Max Viscosity | ≤ 100,000 cP |

Inlet/Outlet | Standard sanitary tri-clamp or flange |

Seal Type | Seal-less or mechanical seal optional |

Motor Options | Electric, variable frequency, or pneumatic drive |

Surface Finish | Ra ≤ 0.8 μm (hygienic standard) |

Cleaning | CIP/SIP compatible |

Direction | Bi-directional capability available |

These parameters make the pump versatile, capable of handling thin liquids, high-viscosity pastes, and shear-sensitive products with minimal degradation. Its compact footprint and modular design facilitate installation in both horizontal and vertical configurations, optimizing space in processing lines.

The G-Type Sanitary Screw Pump is widely used in industries that demand hygienic fluid handling, precision dosing, and consistent output:

Chocolate, syrup, honey, cream, and sauces: Gentle pumping ensures product integrity.

Dairy products: Maintains texture while transferring milk, yogurt, and other dairy liquids.

Juices and liquid concentrates: Minimizes shear and prevents foaming.

Vaccines, injectable solutions, and biofluids: Maintains sterility and prevents contamination.

Cosmetic creams and lotions: Smooth transfer of high-viscosity formulations.

Acids, alkalis, and corrosive chemicals: 316L stainless steel construction ensures durability.

Viscous resins and polymers: Provides consistent flow without clogging.

Laboratory or pilot plant use: Precise dosing and transfer of small volumes.

Cosmetic production lines: Hygienic handling of gels, oils, and emulsions.

To ensure optimal performance and longevity, follow these operational guidelines:

Mounting: Install horizontally or vertically, depending on line layout. Ensure alignment of inlet and outlet.

Connection: Use sanitary tri-clamps or flange connections. Tighten securely to avoid leaks.

Drive Alignment: Connect the pump to the motor or drive system using flexible couplings if needed.

Priming: For viscous liquids, pre-fill the pump cavity or allow gradual start-up to avoid dry running.

Start-Up: Run the pump at low speed initially to prime and avoid sudden pressure surges.

Flow Adjustment: Adjust speed via variable frequency drive (VFD) or motor control to achieve desired flow.

Monitoring: Check for unusual vibrations, temperature rises, or abnormal noise.

Cleaning: Perform regular CIP/SIP cleaning for sanitary compliance. Flush the pump with compatible cleaning solutions after each batch.

Routine Inspection: Check seals, bearings, and rotor for wear.

Lubrication: Ensure proper lubrication of drive components.

Replacement Parts: Use OEM-certified rotors, stators, and seals for consistent performance.

The pump can handle viscous liquids, shear-sensitive fluids, food pastes, pharmaceuticals, and chemical solutions. Maximum viscosity up to 100,000 cP.

Yes, it can handle liquids up to 120°C, and options for higher temperatures are available with upgraded materials or cooling jackets.

It is suitable for mildly abrasive fluids, but for highly abrasive materials, consider abrasion-resistant coatings or heavy-duty rotors.

The pump supports CIP (Clean-In-Place) and SIP (Sterilize-In-Place). Use approved cleaning agents compatible with stainless steel and follow recommended cleaning cycles.

Yes, many G-Type models support bi-directional flow, allowing flexible installation in process lines.

Electric motors, variable frequency drives (VFDs), and pneumatic drives are available to match process requirements.

Ensure proper NPSH (Net Positive Suction Head), avoid dry running, and maintain recommended flow rates.

The G-Type Sanitary Screw Pump is a high-efficiency, food-grade pump designed for precision, hygiene, and versatility. Its 316L stainless steel construction, gentle pumping action, and modular design make it ideal for food, pharmaceutical, cosmetic, and chemical industries. By combining reliable performance, easy maintenance, and strict sanitary compliance, this pump ensures consistent product quality and efficient fluid handling in demanding applications.

Whether for viscous pastes, shear-sensitive fluids, or corrosive chemical solutions, the G-Type Sanitary Screw Pump delivers precision, safety, and durability—making it a cornerstone for modern hygienic processing lines.

Copyright ? Jiangsu Longjie Pump Manufacturing Co., Ltd.