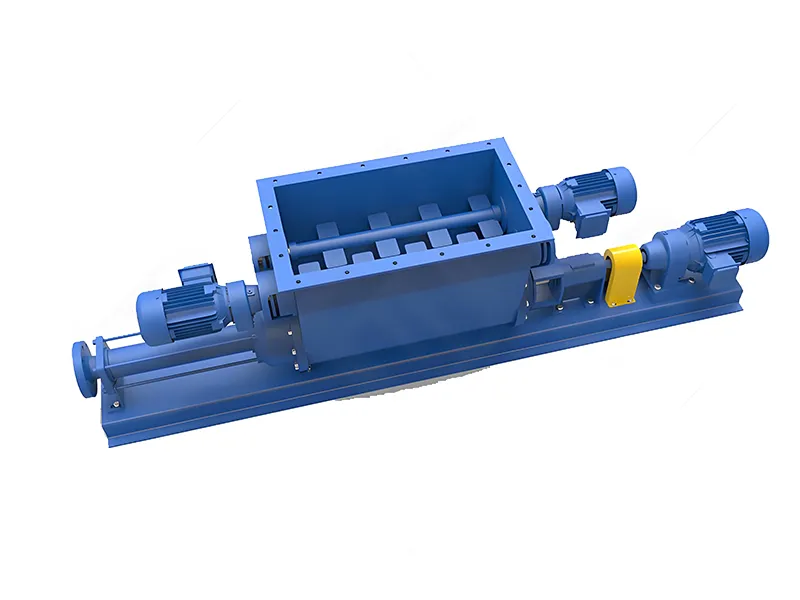

Single Screw Pump with Loose Push

◆Intermediate shaft with loose push.

◆Designed for conveying materials with poor flowability, high viscosity, or easy sedimentation.

◆Flow rate up to 200 m3/h.

◆Pressure up to 2.4 MPa.

Suitable for conveying viscous materials in various applications. With stainless steel flow components and a stator made of food-grade rubber, it can convey foods with poor flowability, such as mashed potatoes, tomato sauce, and pureed meat. Using other materials or a combination of materials, it can also convey media with poor flowability, such as concentrated sludge.

The GS Single Screw Pump with Loose Pusher is an advanced industrial pump designed for handling viscous, high-solid-content, and shear-sensitive materials across multiple industries. Combining the robust GS single-screw pump design with an innovative loose pusher mechanism, this pump ensures efficient material transfer, reduced clogging, and smooth continuous flow even in challenging conditions.

Manufactured from high-quality stainless steel or abrasion-resistant alloys, the GS Single Screw Pump provides exceptional corrosion resistance, durability, and operational reliability. The loose pusher mechanism enables gentle but effective movement of thick or partially solidified materials, minimizing bridging, compaction, and pulsation. This makes it ideal for chemical, food, pharmaceutical, wastewater, and heavy industrial applications where high-viscosity or particulate-laden fluids must be transferred efficiently.

Compact and modular, the pump can be easily integrated into existing process lines, storage tanks, and dosing systems, and offers mechanical seal or seal-less options for hygienic or aggressive fluid handling. Its design ensures reduced wear, lower energy consumption, and simplified maintenance, providing a cost-effective solution for continuous operations.

The GS Single Screw Pump with Loose Pusher is engineered to handle high-viscosity, solid-laden, and shear-sensitive fluids efficiently. Its typical technical specifications include:

| Parameter | Specification |

Pump Type | Single-screw, positive displacement |

Material | 316L Stainless Steel, Duplex, or abrasion-resistant alloys |

Flow Rate | 0.5 – 250 m3/h (depending on model size) |

Maximum Pressure | ≤ 1.5 MPa (15 bar) |

Maximum Temperature | -20°C – 150°C (optional high-temp models up to 250°C) |

Viscosity Range | ≤ 150,000 cP |

Solids Handling | Up to 60% by volume, particle size ≤ 50 mm |

Pusher Mechanism | Loose pusher for bridging and compacted material handling |

Seal Type | Mechanical seal or seal-less magnetic drive optional |

Drive Options | Electric, variable frequency drive (VFD), pneumatic, hydraulic |

Surface Finish | Ra ≤ 0.8 μm (for hygienic applications) |

Cleaning | CIP/SIP compatible (food and pharmaceutical models) |

Flow Direction | Bi-directional capability |

The loose pusher mechanism ensures that viscous or particulate-rich materials do not clog the pump inlet, maintaining a smooth, consistent flow. The rotor-stator design provides minimal pulsation and shear, protecting product integrity while pumping sensitive or high-value materials.

The GS Single Screw Pump with Loose Pusher is versatile and suited for industries requiring reliable, continuous pumping of viscous or particulate-laden fluids.

Thick adhesives and resins: Ensures continuous material transfer from tanks to mixers.

Corrosive pastes and slurries: Stainless steel or alloy construction prevents chemical damage.

Polymers and coating materials: Maintains uniform consistency and prevents pulsation.

Honey, syrups, and sauces: Smooth, contamination-free transfer and batching.

Chocolate, peanut butter, and spreads: Gentle pumping preserves product quality.

Thick dairy products: Efficient pumping of yogurt, cream, and custards.

Ointments, gels, creams, and suspensions: Hygienic and sterile transfer with CIP/SIP compatibility.

Active pharmaceutical ingredients (APIs): Prevents degradation and ensures precise dosing.

Biologics and sensitive formulations: Maintains homogeneity and reduces shear.

Thick sludge pumping: Loose pusher prevents blockages and ensures continuous feeding.

Slurries with high solids content: Efficient transfer without clogging.

Dewatering feed: Smooth pumping to filtration or treatment units.

Mineral slurries: Handles abrasive and high-solid-content materials.

Cement, grout, and construction materials: Prevents bridging and ensures consistent flow.

Industrial pastes: Efficient pumping for large-scale operations.

Proper usage ensures optimal performance, longevity, and safety:

Mounting: Install horizontally or vertically according to process layout.

Connections: Secure inlet and outlet with appropriate flanges or sanitary fittings.

Drive Alignment: Ensure precise alignment with motor, VFD, pneumatic, or hydraulic drive.

Priming: Pre-fill pump or start at low speed for viscous materials to avoid dry running.

Start-Up: Begin at low speed to gently prime viscous or solid-laden fluids.

Flow Adjustment: Adjust pump speed using a VFD or manual control for accurate delivery.

Pusher Adjustment: Operate loose pusher mechanism to prevent material bridging.

Monitoring: Regularly check vibration, temperature, and unusual noises.

Cleaning: For food or pharmaceutical applications, perform CIP/SIP cleaning cycles; for abrasive materials, flush with compatible cleaning agents.

Routine Inspection: Examine rotor, pusher, seals, bearings, and drive components.

Lubrication: Ensure proper lubrication of drive and bearing units.

Replacement Parts: Use OEM-certified components for consistent performance.

Preventive Maintenance: Schedule regular inspections to prevent downtime and extend pump life.

It can handle high-viscosity, shear-sensitive, and particulate-laden fluids, including slurries, pastes, adhesives, sauces, honey, creams, and pharmaceutical gels.

The loose pusher gently moves compacted or bridging material into the pump rotor, preventing clogs and ensuring continuous flow.

Yes, with abrasion-resistant alloys or stainless steel construction, it is suitable for abrasive and corrosive fluids.

Yes, standard models operate from -20°C to 150°C, with optional high-temperature versions up to 250°C.

Yes, hygienic versions are fully compatible with CIP/SIP processes for sterile operation.

Dry running is not recommended. Priming or low-speed start-up is necessary for viscous materials.

Maintain proper NPSH, avoid air pockets, and operate within recommended flow ranges.

Yes, with VFD or variable-speed drive, the pump can provide accurate metering of viscous or particulate-rich fluids.

Prevents Bridging and Clogging: Loose pusher ensures continuous material movement.

Handles Viscous and Solid-Laden Fluids: Efficient for slurries, pastes, and high-solid materials.

Durable Construction: Stainless steel or alloy materials resist wear and corrosion.

Hygienic Options: CIP/SIP compatible for food and pharmaceutical applications.

Pulsation-Free Flow: Rotor-stator design minimizes shear and preserves product integrity.

Versatile Drives: Supports electric, VFD, pneumatic, or hydraulic operation.

Ease of Maintenance: Modular design allows easy inspection and part replacement.

Bi-Directional Flow: Flexible installation and process integration.

The GS Single Screw Pump with Loose Pusher is a reliable, versatile, and high-performance solution for pumping viscous, shear-sensitive, and particulate-laden fluids across multiple industries. The loose pusher mechanism ensures continuous material flow, preventing bridging and blockages even in challenging process conditions.

Ideal for chemical, food, pharmaceutical, wastewater, and heavy industrial applications, the pump delivers durability, efficiency, and precise fluid handling. Its modular design, CIP/SIP capability, and gentle rotor operation make it the preferred choice for engineers, production managers, and quality assurance teams seeking a robust and hygienic solution for complex fluid transfer.

RELATED

RELATED

Copyright ? Jiangsu Longjie Pump Manufacturing Co., Ltd.