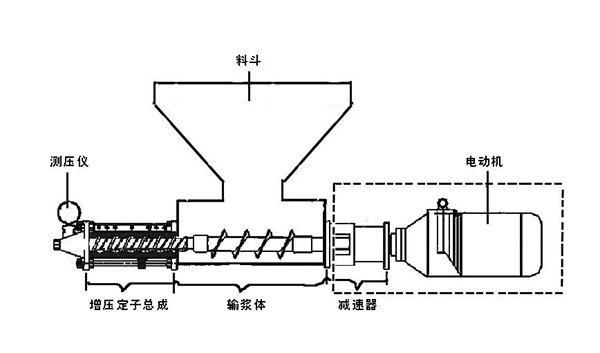

GN Hopper Screw Pump Overview

The hopper screw pump features a rectangular hopper and a propeller on the connecting rod. It is suitable for non-free-flowing media containing liquids. When conveying liquids such as slag, an agitator can also be installed to prevent sedimentation. For high-concentration slags, a large hopper with crushing function can be added to prevent clogging. The pump can be equipped with various drive options, and is most suitable for a three-phase gear reducer motor.

Custom hoppers can be customized for special materials at the inlet according to customer requirements, ensuring smooth feeding and discharge, resulting in pressure-free feeding and discharging, higher pump efficiency, and longer service life, completely eliminating customer problems. Inlet and outlet options include clamp quick-release, flange, internal thread, external thread, and union. Pump body materials include cast iron, 304 stainless steel, 316 stainless steel, and 316L stainless steel, depending on the specific media requirements.

II. Scope of Application

The GN series hopper-type screw pumps utilize a special screw propeller structure at the feed port to convey viscous liquids. Their primary applications are as follows:

Environmental Protection: Transporting industrial and domestic wastewater, sludge containing solid particles and short fibers, and particularly suitable for oil-water separators and plate-and-frame filter presses.

Food Industry: Transporting ketchup, mashed potatoes, peanut butter, yogurt, fresh cream, ice cream, cheese blocks, whey, beer, wort, yeast, fruit juice drinks, vegetable pastes, jams, jellies, etc.

Pharmaceutical Industry: Transporting various types of pill pastes, extracts, emulsifiers, cough syrups, biological products, cod liver oil, royal jelly, etc.

Household Chemical Industry: Transporting shampoo, hand soap, toothpaste, cosmetics, soap, etc.

Paper Industry: Transporting glue, high-viscosity inks, wallpaper, PVC polymer plastic pastes, and pulps of various concentrations and short-fiber slurries.

Petroleum Industry: Transporting crude oil, crude oil-water mixtures, and coalfield gas-water mixtures. Construction Industry: Cement mortar, lime slurry, paint, and paste spraying. Mining Industry: Solid particles in mines, groundwater, and sewage slurry. Chemical Industry: Various suspensions, oils, greases, various colloidal slurries, and various adhesives. Shipbuilding Industry: Wheel bottom cleaning, oil-water, oil residue, and oily wastewater conveying. Industrial boilers and power plants: Coal-water slurry conveying.

Suitable for:

1. Transporting high-viscosity media.

2. Transporting media containing solid particles or fibers.

3. Requires continuous, stable pressure without periodic pressure fluctuations.

4. Requires minimal agitation and no disruption to the inherent structure of the transported media.

5. Low noise.

Copyright ? Jiangsu Longjie Pump Manufacturing Co., Ltd.