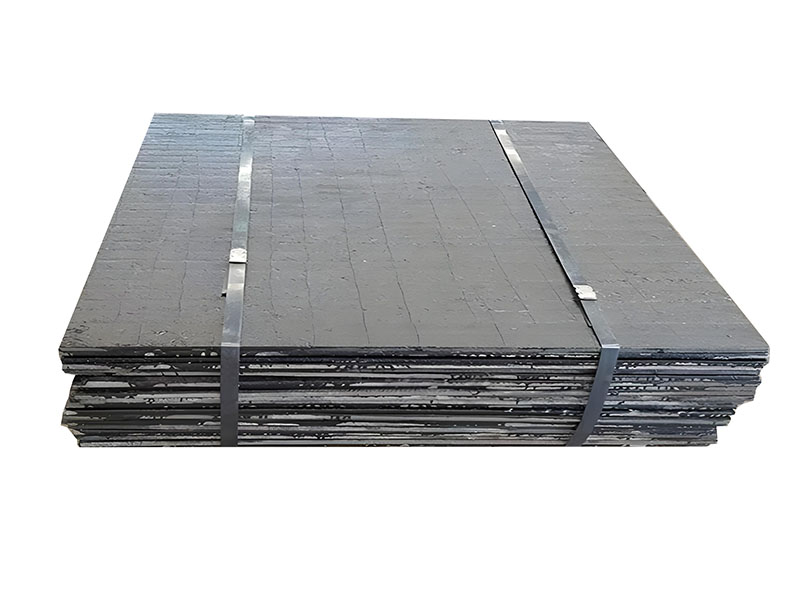

Wear plates are specialized protective components designed to extend the life of industrial equipment by reducing wear and abrasion in high-friction and high-impact environments. Made from high-quality materials such as hardened steel, stainless steel, ceramic composites, and polymer-reinforced alloys, wear plates are essential for maintaining operational efficiency, reducing downtime, and minimizing maintenance costs.

These plates are widely used in mining, cement, chemical, power generation, food processing, and material handling industries. Wear plates protect conveyors, chutes, hoppers, pumps, valves, and industrial machinery from damage caused by abrasive materials, corrosive substances, and continuous mechanical impact.

Wear plates are engineered to withstand extreme temperatures, chemical corrosion, and mechanical stress while maintaining dimensional stability. Depending on the application, they can be replaceable, bolted, or welded in place, allowing for easy maintenance and quick replacement.

With advanced heat treatment, surface hardening, and material engineering, modern wear plates achieve longer service life, lower friction, and improved resistance to chemical attack, providing industries with a cost-effective solution for equipment protection.

High Wear and Abrasion Resistance

Protects machinery from sand, coal, ores, chemicals, and other abrasive materials.

Reduces equipment downtime and maintenance frequency.

Corrosion and Chemical Resistance

Available in stainless steel, alloy steels, and coated materials.

Suitable for acidic, alkaline, or chemically aggressive environments.

Heat and Impact Resistance

Can withstand high-temperature operations and mechanical shocks.

Maintains structural integrity under extreme industrial conditions.

Versatile Installation Options

Wear plates can be bolted, welded, or clamped, depending on operational needs.

Designed for easy replacement without extensive downtime.

Customizable Design

Thickness, material, and dimensions can be tailored to specific applications.

Enables optimal protection and performance for each piece of equipment.

Cost-Effective Protection

Reduces equipment wear, maintenance costs, and operational disruptions.

Extends the lifetime of expensive machinery components.

Low Friction Surface

Engineered for smooth material flow and reduced energy consumption in conveyors or chutes.

| Parameter | Specification Range |

Material of Construction | Hardened steel, stainless steel, alloy steel, ceramic composites |

Hardness | 40–70 HRC depending on material and application |

Thickness Range | 3 mm – 50 mm or customized |

Surface Treatment | Heat-treated, laser-hardened, plasma-coated, polymer-coated |

Operating Temperature | -40°C to +600°C depending on material |

Chemical Resistance | Resistant to acids, alkalis, solvents |

Abrasion Resistance | High-abrasion materials protection (ASTM G65 standard reference) |

Installation Type | Welded, bolted, clamped, adhesive-mounted |

Dimensions | Customizable to client specifications |

Lifespan | 2–10x longer than unprotected surfaces depending on wear conditions |

Weight | Varies depending on thickness, material, and size |

Protects conveyor chutes, ore bins, hoppers, and crushers from abrasive ores and rock.

Reduces machine wear, maintenance, and downtime, improving operational efficiency.

Shields cement mills, crushers, material chutes, and conveyor belts from wear caused by sand, gravel, and cement clinker.

Enhances production efficiency and equipment life.

Protects chemical storage tanks, pipelines, valves, and agitators from corrosive chemicals.

Resists acid, alkali, and solvent attack, maintaining safe and continuous operations.

Applied in coal handling systems, ash chutes, and turbines to reduce abrasion and corrosion damage.

Improves plant reliability and reduces maintenance costs.

Ensures food-grade wear protection for bulk material handling equipment.

Stainless steel wear plates prevent contamination while resisting abrasion.

Used in conveyors, hoppers, chutes, and feeders to protect against friction and impact from bulk materials.

Reduces energy consumption by providing low-friction surfaces.

Protects pumps, agitators, and chemical slurry lines from abrasion and corrosion.

Extends component life and reduces downtime.

Wear plates are customizable for high-wear contact surfaces in industrial machinery and fabrication processes.

Surface Preparation

Clean the base surface of dirt, rust, or residues.

Ensure the surface is flat and even for optimal adhesion or welding.

Mounting Options

Welded: Align and tack weld, then complete full weld.

Bolted: Drill precision holes and secure with high-strength bolts.

Clamped or Adhesive-mounted: Ensure uniform pressure for adhesion.

Alignment and Fit

Ensure wear plates are flush with the base surface to avoid gaps or misalignment.

Wear plates do not require active operation but must withstand impact, abrasion, and chemical exposure.

Monitor surface wear regularly and replace when thickness reduces beyond safety threshold.

Inspect wear plates at scheduled intervals, depending on abrasion level.

Replace or rotate plates before significant base material exposure occurs.

Clean with non-abrasive tools if chemical residues accumulate.

| Problem | Possible Cause | Solution |

Premature wear | Improper material selection | Use higher hardness or corrosion-resistant material |

Plate detachment | Poor welding or mounting | Reinstall with proper welding/bolting techniques |

Corrosion or chemical damage | Incompatible material | Switch to chemical-resistant alloy or fluoropolymer lining |

Warping or deformation | High temperature or mechanical stress | Use heat-treated or thicker wear plates |

Abrasive particle embedding | Excessive impact or contamination | Regular cleaning and replace with harder material |

Uneven wear | Improper alignment or installation | Ensure flat surface and correct orientation |

Extended Equipment Life – Protects machinery surfaces, reducing replacement frequency.

Reduced Maintenance Costs – Less downtime and fewer component replacements.

Customizable Design – Tailored to specific equipment and wear conditions.

High Corrosion Resistance – Handles acids, alkalis, and chemical solutions safely.

Impact and Heat Resistance – Maintains integrity under heavy load and high temperature.

Easy Installation and Replacement – Bolted, welded, or clamped options for convenience.

Low Friction – Smooth surfaces reduce energy consumption in conveyors or hoppers.

Wide Industrial Applications – Mining, chemical, cement, food, power, and material handling.

Conclusion

Wear plates are a vital component in protecting industrial equipment from abrasion, corrosion, and impact, significantly reducing maintenance costs, downtime, and operational disruptions. With customizable design, high durability, chemical resistance, and ease of installation, wear plates ensure long-lasting performance across various industries, including mining, chemical, food, cement, and material handling sectors.

Copyright ? Jiangsu Longjie Pump Manufacturing Co., Ltd.