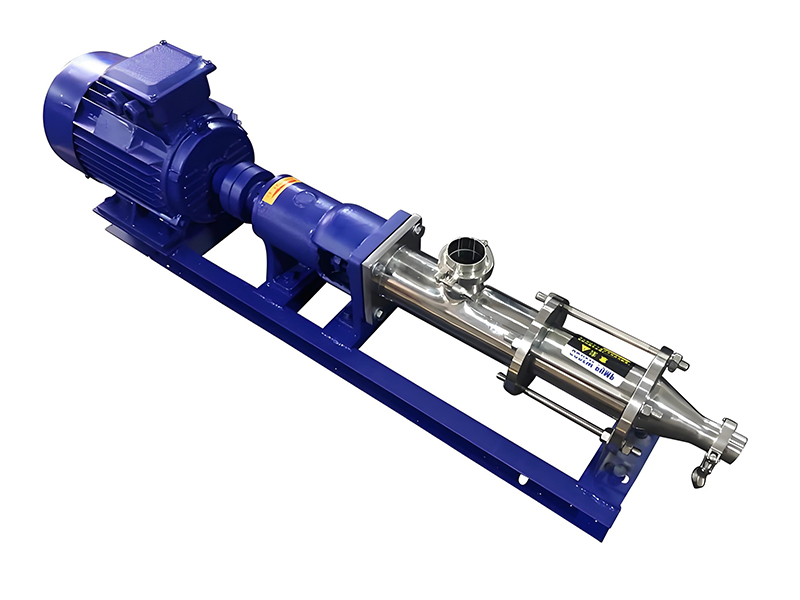

Explosion-Proof Horizontal Single-Screw Pump | Reliable Solution for Hazardous Fluid Transfer

The Explosion-Proof Horizontal Single-Screw Pump is a highly efficient positive displacement pump designed for safe and reliable transfer of viscous, abrasive, or volatile fluids in hazardous industrial environments. Built with explosion-proof motors and durable stainless-steel components, this pump provides stable operation in areas where flammable gases, vapors, or dust may be present.

This pump belongs to the G-type Progressive cavity pump series, featuring a horizontally mounted rotor and stator assembly that delivers smooth, pulsation-free flow. Its explosion-proof design makes it suitable for petrochemical plants, paint workshops, oil refineries, wastewater treatment facilities, and chemical manufacturing lines, where safety and precision are essential.

Unlike centrifugal pumps, the single-screw design offers constant volumetric efficiency, minimal shear, and excellent handling of high-viscosity and solids-laden media. The explosion-proof motor ensures ignition prevention even under challenging operating conditions.

The explosion-proof horizontal single-screw pump is widely adopted in industries handling crude oil, solvents, lubricants, adhesives, slurry, and wastewater, offering dependable performance, easy maintenance, and long service life.

Explosion-Proof Design:

Equipped with explosion-proof motors certified to ATEX or IECEx standards, ensuring safe operation in flammable and explosive environments.

Stable Flow Delivery:

Continuous, non-pulsating output suitable for metering, dosing, and feeding viscous or abrasive fluids.

Excellent Self-Priming Capability:

Can handle suction lifts up to 8 meters depending on fluid viscosity, without the need for additional priming systems.

High Efficiency with Viscous Media:

Maintains consistent performance even when transferring oils, sludges, resins, or slurries.

Corrosion and Wear Resistance:

Available in stainless steel (304, 316L) or cast iron construction, offering durability against corrosive or abrasive media.

Compact Horizontal Design:

Space-saving horizontal layout suitable for skid installations, chemical dosing systems, or portable pump stations.

Low Noise and Vibration:

Smooth progressive cavity operation ensures quiet, low-impact running.

Easy Maintenance:

Simple structure with replaceable stator and rotor components reduces downtime and maintenance costs.

| Parameter | Specification Range |

Model | G-type Explosion-Proof Horizontal Single-Screw Pump |

Flow Rate | 0.5 m3/h – 100 m3/h (customizable) |

Pressure | Up to 1.2 MPa |

Temperature Range | -20°C to 120°C (optional up to 180°C) |

Viscosity Range | Up to 1,000,000 cP |

Speed | 200 – 1000 rpm |

Material (Wet Parts) | Cast iron, SS304, SS316L |

Seal Type | Mechanical seal or packing seal |

Drive Type | Explosion-proof electric motor or geared drive |

Installation Position | Horizontal |

Explosion-Proof Grade | Ex d IIB T4 / Ex d IIC T4 (custom options available) |

Connection Type | Flange or thread connection |

Lubrication | Oil bath or grease lubrication |

Power | 0.75 kW – 45 kW depending on model |

The explosion-proof horizontal single-screw pump operates using a progressive cavity principle. The rotor, a helical screw made of hardened steel, rotates inside a double-threaded elastomer stator. As the rotor turns, cavities are formed and move progressively from suction to discharge, pushing the fluid smoothly through the pump chamber.

This unique working mechanism ensures:

No pulsation, protecting sensitive materials such as emulsions or chemicals.

Low shear rate, preserving product integrity.

Capability to handle abrasive or viscous materials without clogging.

High suction lift with excellent self-priming capability.

Since the motor is explosion-proof, it prevents ignition by isolating any sparks generated inside, ensuring complete safety during fluid transfer in volatile environments.

The Explosion-Proof Horizontal Single-Screw Pump is suitable for a wide range of industries and applications, including:

Crude oil transfer

Solvent delivery

Chemical mixing and feeding

Lubricant or additive circulation

Paint blending and transfer

Solvent-based coating handling

Pigment slurry transport

Sludge transfer in treatment plants

Dewatered sludge feeding

Oil-water separation systems

Handling of syrup, honey, molasses, or dairy waste (with stainless-steel sanitary models)

Alcohol or solvent-based flavoring transfer

Grout and slurry transfer

Cement additive dosing

Viscous liquid dosing

Corrosive or explosive fluid transfer

Fine chemical blending

Installation Site:

Install the pump on a solid, level surface with good ventilation. Ensure adequate clearance for maintenance.

Pipeline Connection:

Connect suction and discharge pipelines properly. Ensure air-tight sealing to maintain vacuum for self-priming operation.

Electrical Setup:

The explosion-proof motor must be wired by certified personnel. Confirm voltage, frequency, and explosion-proof compliance before start-up.

Priming and Start-up:

Fill the pump chamber with a small amount of liquid before first use.

Do not run dry; dry operation may damage the stator.

Start the motor slowly and gradually increase speed.

Operation Monitoring:

Regularly monitor pressure, temperature, and flow rate.

Check for vibration or abnormal noise.

Ensure the mechanical seal or packing gland is functioning correctly.

Shutdown Procedure:

Turn off the power and relieve pressure before maintenance.

Drain residual liquid to prevent chemical corrosion or sedimentation.

Regular Maintenance:

Lubricate bearings and joints periodically.

Replace worn stator or rotor components to maintain efficiency.

Clean internal cavities to avoid clogging.

Inspect mechanical seals for leaks or wear.

Common Troubleshooting:

| Problem | Possible Cause | Solution |

No flow or low flow | Air trapped, worn rotor/stator | Vent air, replace worn parts |

Excessive vibration | Misalignment, foreign matter | Re-align pump, clean chamber |

Leakage at seal | Damaged seal ring or improper installation | Replace seal, adjust packing |

Overheating | Dry running, excessive pressure | Ensure proper lubrication and priming |

Noise from motor | Bearing wear or electrical fault | Replace bearing, check motor wiring |

High safety level for flammable environments.

Low energy consumption due to efficient volumetric transfer.

Minimal pulsation and noise ideal for sensitive process lines.

Versatile handling of thick, thin, abrasive, or gaseous fluids.

Customizable design for different materials, speeds, and sealing systems.

Long service life due to wear-resistant rotor and stator materials.

Always check explosion-proof certification before operation.

Avoid direct exposure to flammable gases during maintenance.

Ensure proper grounding of electrical connections.

Do not run the pump without liquid (dry running causes severe stator damage).

Keep away from high-voltage areas during operation.

Q1: What makes this pump explosion-proof?

A: The motor and junction box are designed to contain and isolate any internal sparks or explosions, preventing ignition of external gases or vapors.

Q2: Can it handle high-viscosity fluids?

A: Yes. The single-screw mechanism efficiently transfers fluids with viscosities up to 1,000,000 cP, including sludge, oil, and slurry.

Q3: What materials are available for the pump?

A: The pump body can be made from cast iron, SS304, or SS316L depending on fluid corrosiveness and operating environment.

Q4: What is the maximum temperature the pump can handle?

A: Standard models operate up to 120°C, while special high-temperature versions can handle up to 180°C.

Q5: Is it suitable for outdoor or mobile installations?

A: Yes. The horizontal design allows it to be mounted on mobile skids or fixed platforms.

Q6: How often should maintenance be performed?

A: Depending on fluid characteristics, inspect seals and stators every 6–12 months for optimal performance.

The Explosion-Proof Horizontal Single-Screw Pump provides a safe, efficient, and durable solution for transferring flammable, viscous, and abrasive media across diverse industries. With its progressive cavity technology, explosion-proof motor, and corrosion-resistant construction, it ensures steady flow, low maintenance, and high operational safety in hazardous zones.

Whether used in oil refineries, chemical plants, or wastewater treatment systems, this pump guarantees reliability under the toughest conditions — making it a top choice for industries that demand both performance and explosion-proof protection.

Copyright ? Jiangsu Longjie Pump Manufacturing Co., Ltd.